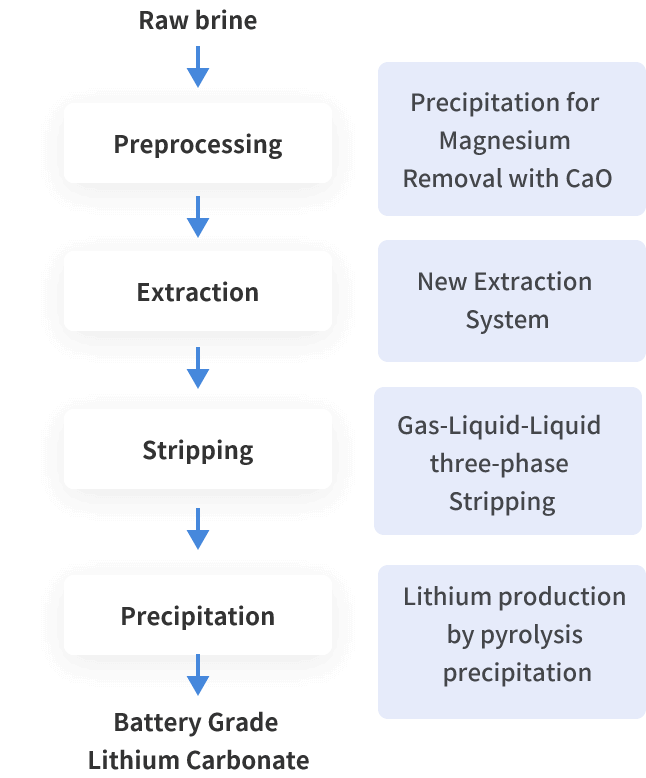

The project has reached production capacity for more than one and a half years. The direct production cost per ton of LiCl (or Li2CO3) has been reduced to 30%. and the lithium yield is greater than 95%.

The LiCl concentration in the concentrated solution is concentrated 25 times at a time to reach more than 200g/L, and the lithium/magnesium separation coefficient is greater than 12000.

This production line is the one with the least investment in fixed assets, the lowest operating cost, and the lowest energy consumption, electricity consumption and fresh water consumption among the industrialized salt lake lithium extraction production lines.

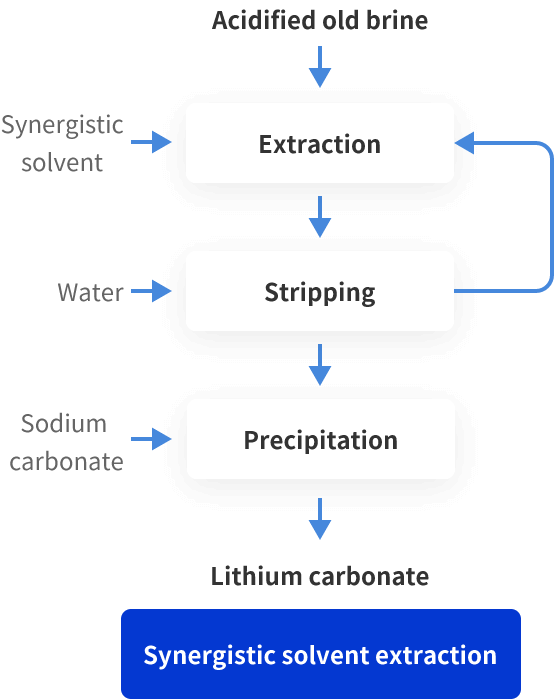

Stripping with water, no acid consumption

The organic phase recycles directly without consuming alkali

The process is shorter, more energy-efficient and more economical

The labor intensity is lower and the working environment has been significantly improved

Factory Appearance

Factory Appearance

Pretreatment Workshop

Pretreatment Workshop

Extraction Workshop

Extraction Workshop

Carbonization Stripping Workshop

Carbonization Stripping Workshop

Pyrolysis Workshop

Pyrolysis Workshop

Dry & Packing Workshop

Dry & Packing Workshop

A pilot production line of 100 tons/year of battery-grade lithium carbonate was established in the Tibet Salt Lake mining area at an altitude of 4,600 meters (the highest in the world for extracting lithium from salt lakes) and was successfully put into production.

The lithium yield is greater than 96%. In the raffinate, the Li concentration is less than 10ppm, and the COD is less than 15ppm. The purity of lithium carbonate is greater than 99.8%, reaching the battery-grade standard. In principle, it has achieved a breakthrough in the production of battery-grade lithium carbonate by one-step lithium extraction from global industrialized salt lakes.

There are a lot of sodium ions and potassium ions in brine, which is difficult to separate from lithium.

In Tibet: high altitude, low temperature, harsh environment, fragile ecology, shortage of conventional energy sources, lagging infrastructure construction, high transportation costs, weak industrial base ...